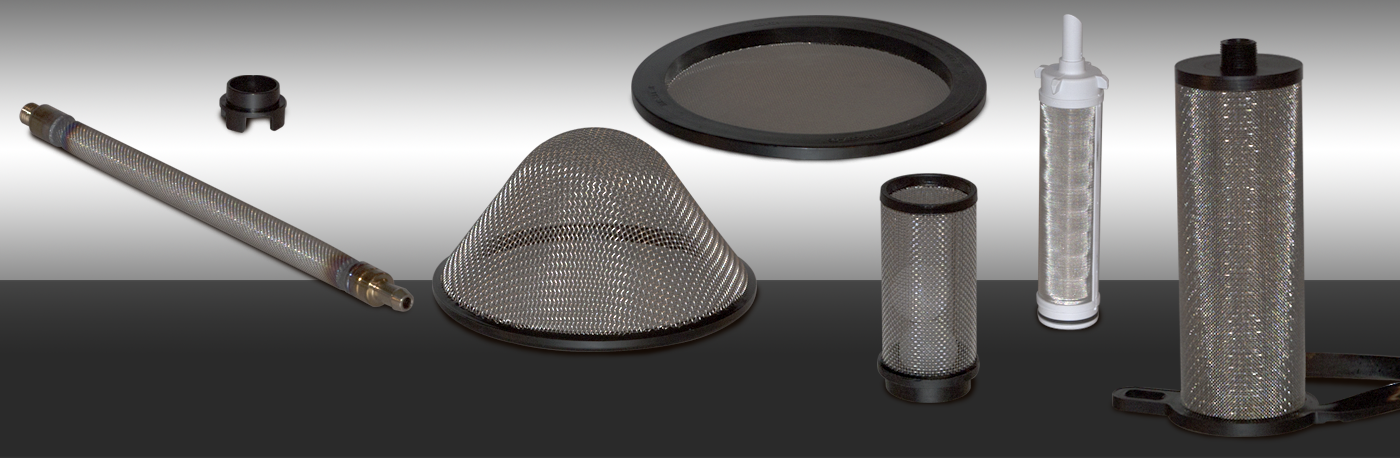

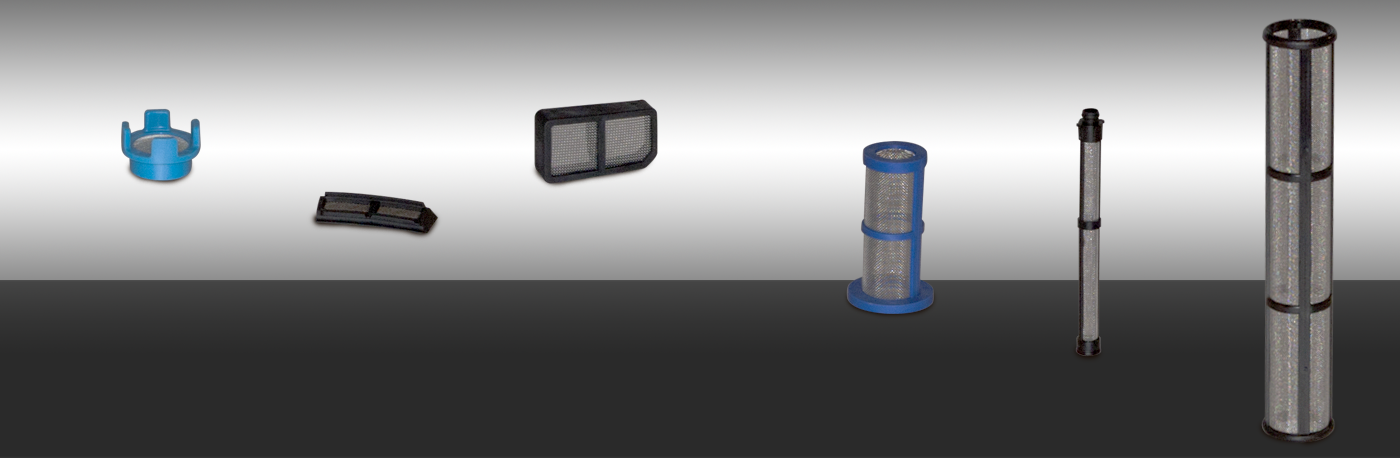

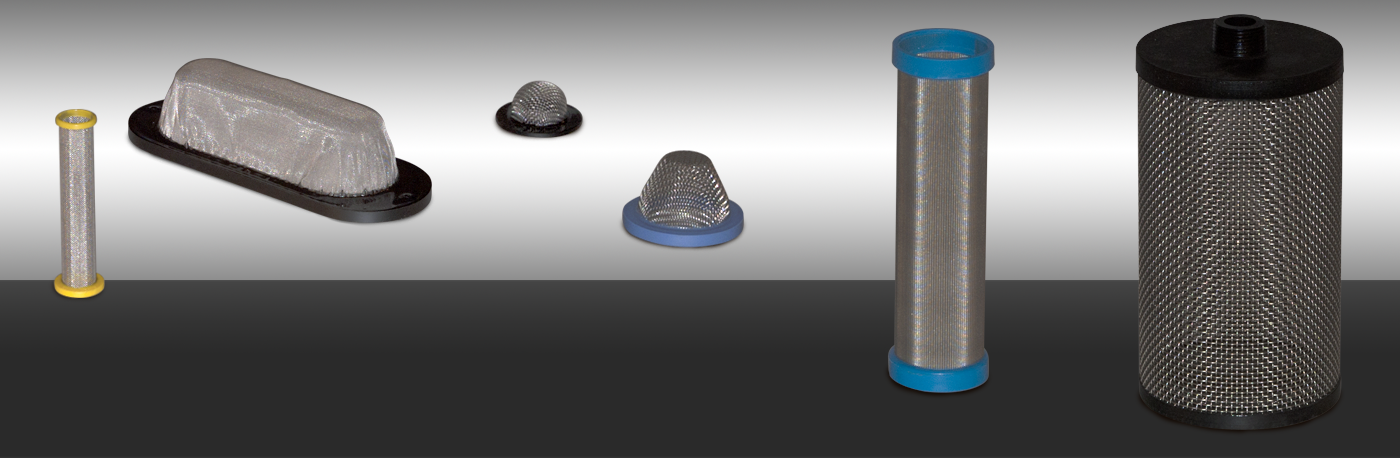

Custom Products

Ron-Vik has over 70 years of experience developing and manufacturing custom product solutions for our customer's straining and filtration needs. We employ an experienced staff of engineers and toolmakers to assist in the design of, and frequently build the tooling necessary to manufacture custom products combining wire or synthetic mesh with thermo-plastic and/or plastisol. We have a wide variety of manufacturing processes at our facility. Our current production includes horizontal and vertical injection molding, pot molding, spin welding, seam welding, induction welding, soldering, stamping, slitting and shearing. We are also capable of CNC turning & milling metal components for products requiring them. This allows us to design and manufacture the most cost effective product solution and to ensure quality in every step of the process.

Many of our custom product solutions are molded from mesh and plastic, utilizing our insert injection molding or pot molding capabilities. These processes allow for flexibility in design and material selection. They also offer significant advantages in cost and ease of manufacture over other potential solutions.

Insert Injection Molding

Ron-Vik has years of experience in manufacturing insert injection molded filters for our proprietary in-line strainers. We have expanded our insert injection molding capabilities to allow us to design and manufacture a wide range of insert molded custom products. Most of these products combine cylinders or flat blanks with thermoplastics or thermoplastic elastomers (TPE's). These products offer significant advantages over metal on mesh, welded or soldered designs. These components are made by taking a prefabricated mesh form and putting it into an injection mold. The mold closes around the mesh and plastic is injected to create a gasket and/or a support cage. Mesh sizes range from 10 micron openings up to 2000 micron openings. Our experienced engineering staff will assist you in the design of a component that will achieve your desired results.

Common Materials

Support cage/gasket materials- Nylon: most varieties including filled

- Polypropylene: homopolymers and copolymers including filled

- Polyethylene: high density and low density

- Polyester: most varieties including filled

- Acetal: homopolymers and copolymers including filled

- Santoprene® in most durometers

- Geolast® in most durometers

- Others: contact us if you need a material that is not listed

Filter Materials

- Stainless steel: most alloys, 10 to 2000 micron

- Other metals: most alloys including epoxy and Teflon coated

- Nylon from 10 to 2000 micron

- Polyester from 10 to 2000 micron

- Polypropylene from 75 to 2000 micron

Plastisol Molding

For over 70 years Ron-Vik has been the leader in PVC pot molded filters and strainers. Our pot molding capability combines the efficient filtration of wire mesh with economical PVC flanges and/or gaskets to provide a wide array of filtration and straining products. We can mold cylinders and formed blanks with either rigid or flexible gaskets/flanges. PVC is available in a wide variety of colors and durometer ranges from 40 Shore A to 60 Shore D.

The user is responsible for determining whether the Ron-Vik product is fit for a particular purpose and is suitable for the user's application. Ron-Vik's liability shall be limited to the stated selling price of any defective goods, and shall in no way include the user’s lost profits or goodwill or any other special or consequential damages incurred by the user.