In-Line Strainers

Ron-Vik in-line strainers have been the industry standard for cost effective straining and filtering since they were first introduced over thirty years ago. Applications are wide ranging and include: agricultural sprayers, pressure washers, floor scrubbers, and pre-filters. They are available in port sizes from 1/8" to 1 ½". Port styles currently offered include FNPT, MNPT, HB, and Quick Connect. The current housing materials offered are 6/6 nylon, 20% glass filled polypropylene, and clear nylon (for bowls only). Standard filter elements are available in 20, 50, 80, and 50x250 mesh T304 stainless steel or 70 micron PE. The gasket materials currently offered are EPDM, Buna, and Viton. Not for use with residential water systems.

Customization Available

- Company name or logo molded on the top

- Color of the material for the top and bowl

- Mesh size of the screen

Tops

In-line strainer tops are available in either black 20% glass filled polypropylene or white 6/6 nylon materials. Ron-Vik offers a variety of port types and sizes.

Male NPT - available in 1/8", 1/4", 3/8" and 1/2" in the Low Profile and Low Profile Long Series

Female NPT - available in 1/8", 1/4", 3/8", 1/2", 3/4", 1", 1 1/4" and 1 1/2"

Hosebarb - available in 1/4", 3/8", 1/2" in the Low Profile and Low Profile Long Series

Quick connect fitting - available for 1/4" and 3/8" OD tubing in the Low Profile and Low Profile Long Series

Existing tooling available for reversed arrow direction, BSP threads, & tabs in the Regular Series.

Ron-Vik offers four sizes of bowls, one for each of the product series. The top-bowl connection is a buttress thread to prevent cross threading. For application flexibility, the bowls are offered in 20% glass filled polypropylene, 6/6 nylon, and clear nylon. We also offer a catch basin bowl with a 1/2" NPT connection in our Regular Series Strainers

mesh sizes are 20, 50, 80 and 50x250

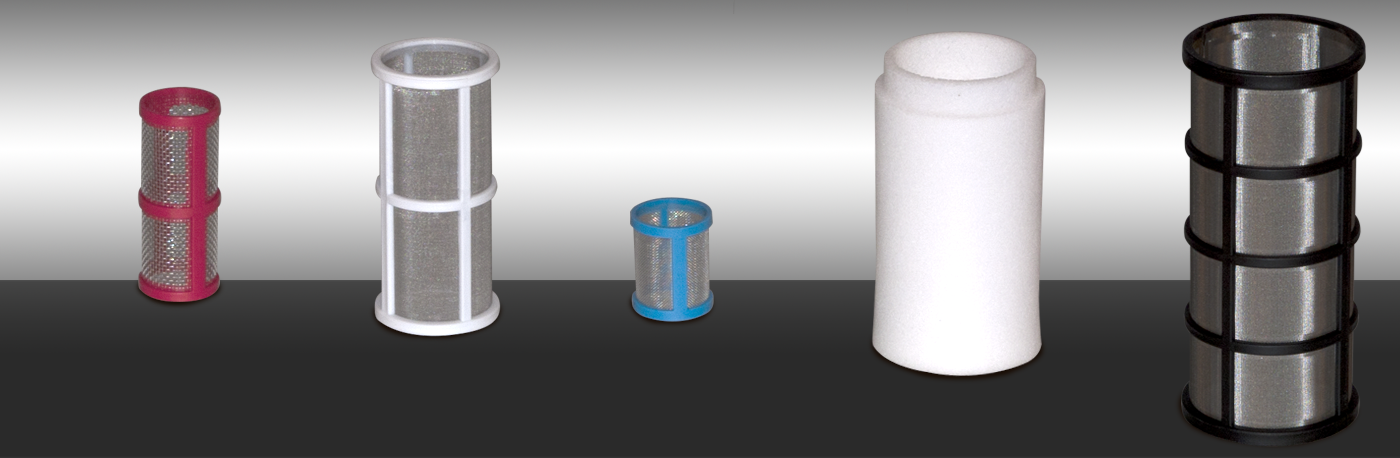

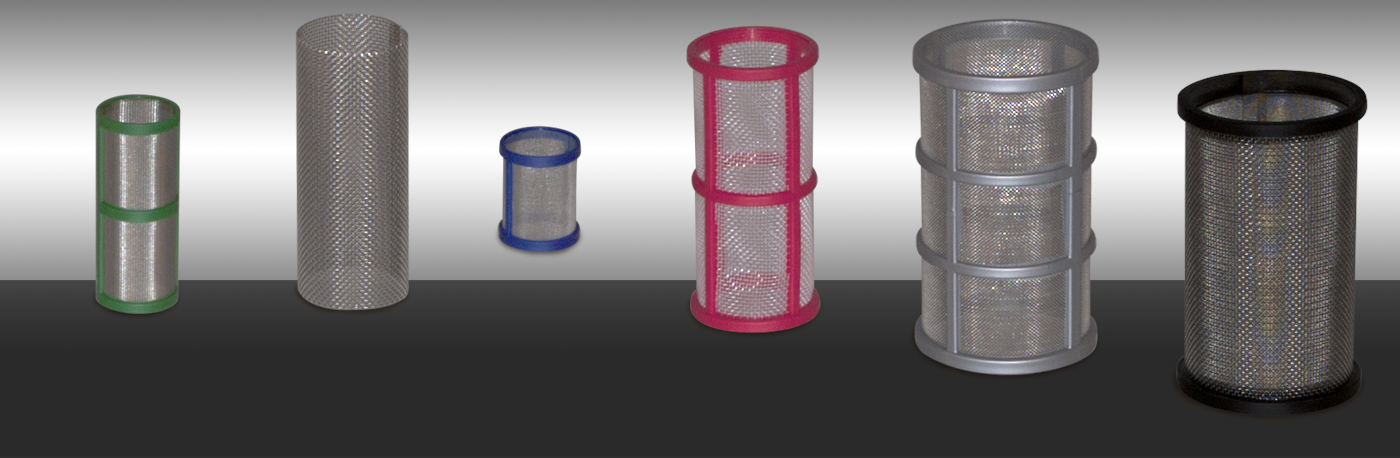

Filter Elements

- Wire mesh screen is the most common element utilized in the in-line strainer assemblies. Our standard caged stainless steel mesh sizes are 20, 50, 80 and 50x250.

- Polyethylene (PE) filters are offered in the low profile, low profile long, regular, and large series. The filter is a depth type filter making it non-cleanable.

Standard Caged Stainless Steel Elements

| Mesh Count | Micron Nominal |

| 20x20 | 915 |

| 50x50 | 305 |

| 80x80 | 178 |

| 50x250 | 40 |

| PE | 70 |

and caged synthetic mesh elements.

Custom Elements

Ron-Vik offers custom molded and caged synthetic mesh elements. Please contact us for more information and minimums.

Low Profile and Low Profile Long Series

Low profile in-line strainers require a minimum amount of space. To increase filter area the low profile tops can be matched with a longer bowl, (referred to as the Low Profile Long Series). The chart below shows reference dimensions for assemblies.

| Series | Style | Sizes | Port-to-Port | Height | Depth | Filter Area |

Low Profile |

FNPT | 1/8, 1/4, 3/8, 1/2 | 3.00 | 2.42 | 1.89 | 3.95 |

| MNPT | 1/8, 1/4, 3/8, 1/2 | 3.05 | 2.42 | 1.89 | 3.95 | |

| Hose Barb | 1/4, 3/8, 1/2 | 3.01 | 2.42 | 1.89 | 3.95 | |

| JG | 1/4 and 3/8 | 2.95 | 2.42 | 1.89 | 3.95 | |

LP Long |

FNPT | 1/8, 1/4, 3/8, 1/2 | 3.00 | 3.75 | 1.89 | 7.71 |

| MNPT | 1/8, 1/4, 3/8, 1/2 | 3.05 | 3.75 | 1.89 | 7.71 | |

| Hose Barb | 1/4, 3/8, 1/2 | 3.01 | 3.75 | 1.89 | 7.71 | |

| JG | 1/4 and 3/8 | 2.95 | 3.75 | 1.89 | 7.71 |

Regular Series

This series is the most commonly used due to it's compact size yet large filter area. Some of the applications for this series include dental supply, commercial and industrial pumps, agricultural and marine. The standard port is NPT. This series is also available with BSP (Higher minimums apply). We now offer a catch basin bowl in this series. The bowl is made of clear nylon with a threaded 1/2" NPT port.

| Series | Port-to-Port | Height** | Depth | Filter Area | |

Regular (FNPT) |

3/8" & 1/2" | 3.55 | 5.38 | 2.92 | 17.73 |

| 3/4" | 3.59 | 5.38 | 2.92 | 17.73 | |

| 1" | 4.15 | 5.70 | 2.92 | 17.73 | |

** Please add 1.5" if using a catch basin bowl.

Large Series

This series is our largest capacity strainers. They are used primarily in the same applications as the intermediate series where increased flow rate and filtration area is required. Available in port sizes from 1" to 1-1/2".

| Series | Port-to-Port | Height | Depth | Filter Area | |

Large (FNPT) |

1" | 4.93 | 6.40 | 4.00 | 29.73 |

| 1 1/4" | 4.93 | 7.13 | 4.00 | 31.84 | |

| 1 1/2" | 5.10 | 8.10 | 4.00 | 38.27 | |

Technical Information

Cleaning Requirements

All wire mesh elements can be easily cleaned or replaced, without removing the entire strainer from the line, by removing the bowl. Do not use chemicals incompatible with the plastic components for cleaning.

Chemical Compatibility

The customer must confirm the chemical compatibility of the in-line strainer components for their use.

Pressure Ratings

All of Ron-Vik's in-line strainer assemblies perform at pressures up to 150 psi at 70 degrees F and 100 psi at 125 degrees F.

Pressure Spikes

Ron-Vik's in-line strainers are not designed for applications where pressure spikes or water hammer is expected. Not for use in residential water systems.

NSF/FDA

Most of Ron-Vik's in-line strainers are eligible for NSF/FDA certification as part of your product. They are not individually certified. Please contact us for specific information.

The user is responsible for determining whether the Ron-Vik product is fit for a particular purpose and is suitable for the user's application. Ron-Vik's liability shall be limited to the stated selling price of any defective goods, and shall in no way include the user’s lost profits or goodwill or any other special or consequential damages incurred by the user.